Common Cable Assemblies Used in Modern Industrial & Enterprise Applications

Download the Full Whitepaper (PDF)Executive Summary

Key Takeaways:

- Use PUR, LSZH, or TPE jackets to handle mechanical and chemical stress.

- Always choose IP67/IP68 connectors for outdoor or wash-down areas.

- Shielded cabling is essential in high-EMI environments.

- Follow TIA, IEC, and UL standards for performance and safety compliance.

- Future-proof designs with PoE, fiber backbones, and hybrid cabling.

Why Cable Assemblies Matter

In many industrial and enterprise applications advanced connectivity is the new norm. This change in paradigms comes in the wake of many developments and the growth of wireless technologies, digitization of sensors, greater sensor integration, electrification of previously mechanical/hydraulic systems, and the thirst for more actionable data in virtually all instances. The only way to provide access to these new electronically sophisticated edge-applications is to have more capable infrastructure that supports the transportation of this data and signals between the cloud and the edge. This is where industrial and enterprise connectivity comes into play. The myriad of applications and the requirements for these applications has driven an ecosystem of various types of interconnect, some highly specialized and some more general

Industrial/Enterprise Peripheral & Miscellaneous Cable Assemblies

- IEEE-488 GPIB Cables

- SCSI Cables

- eSATA Cables

- IEEE-1394 Firewire Cables

- DIN & Mini DIN Cables

- MRJ21 Cables

- TELCO Cables

Recommendations

- For Engineers: Prioritize cables with appropriate EMI shielding and mechanical ratings for the installation environment.

- For System Integrators: Standardize common connector types (RJ45, USB-C, M12) to simplify field maintenance.

- For OEMs: Partner with trusted manufacturers like L-com to develop custom assemblies for specialized products.

- For Network Managers: Use Cat6a or higher Ethernet cables and fiber optics for future-ready infrastructures.

- For Maintenance Teams: Regularly inspect connectors and cabling to prevent data loss or signal degradation.

Ethernet Cable Assemblies (Cat5e, Cat6, Cat6a)

Ethernet cables are one of the most common cable types used for Information Technology (IT) networking, security, power/communication for sensors, and more recently for industrial control and connectivity. Ethernet cables generally consist of four twisted pairs of conductive copper wiring contained within a pliable jacket material. These cables can either be shielded twisted pair (STP) or unshielded twisted pair (UTP) cabling. STP is used in areas of high electromagnetic interference, or when critical data transfer is occurring. UTP is a less expensive cable type but provides less electromagnetic shielding to the signals carried by the twisted pair conductors and could unintentionally conduct interference to connected equipment.

Ethernet cables are sold as conforming to TIA/EIA-586 standards rating based on several categories and subcategories. The most common Ethernet cable categories are 5, 5e, 6, and 6A, but the latest Category 7, 7a, and 8 cables are used in the most advanced applications for the highest data rates with 10 Gbps, 25 Gbps, and 40 Gbps core infrastructure, respectively. The Ethernet categories specify the minimum capabilities of a given cable from a networking perspective, but do not provide details of the appropriate use of the cabling, shielding, f ire-rating, etc. These are additional considerations that must be navigated when selecting an ethernet cable for a given application.

| Ethernet Categories Top Specifications | ||||

|---|---|---|---|---|

| Category | Max. Data Rate | Bandwidth | Max. Distance | Usage |

| Category 3 | 10 Mbps | 16 MHz | 100 m / 328 ft. | 10BaseT Ethernet |

| Category 4 | 16 Mbps | 20 MHz | 100 m / 328 ft. | Token Ring |

| Category 5 | 100 Mbps | 100 MHz | 100 m / 328 ft. | 100BaseT Ethernet |

| Category 5e | 1 Gbps | 100 MHz | 100 m / 328 ft. | 100BaseT Ethernet, residential |

| Category 6 | 1 Gbps | 250 MHz | 100 m / 328 ft. 10Gb at 37 m / 121 ft. |

Gigabit Ethernet, commercial buildings |

| Category 6a | 10 Gbps | 500 MHz | 100 m / 328 ft. | Gigabit Ethernet in data centers and commercial buildings |

| Category 7 | 10 Gbps | 600 MHz | 100 m / 328 ft. | 10 Gbps Core Infrastructure |

| Category 7a | 10 Gbps | 1000 MHz | 100 m / 328 ft. 40Gb at 50 m / 164 ft. |

10 Gbps Core Infrastructure |

| Category 8 | 25 Gbps-Cat8.1 40 Gbps-Cat8.2 |

2000 MHz | 30 m / 98 ft. | 25 Gbps/40 Gbps Core Infrastructure |

Some Ethernet cables are made to rugged standards for more industrial applications, and this often involves adding a foil/braided shield within the cable jacket, a cross divider between the twisted pairs, shielding around each twisted pair, cable armoring, and more rugged insulation types. There are also application specific types of Ethernet cables, such as slim/thin cables, flat cables, coiled cables, etc.

RJ45 is the most common type of Ethernet connector, and hence these connectors come in a wide variety of formats. Some are basic economy RJ45 connectors that are made for economical installations and have no environmental protections, and others can be more ruggedized and include locking/threaded protective sleeves that provide high levels of environmental protection.

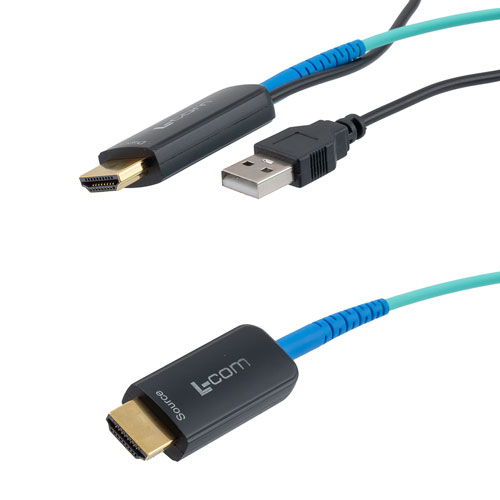

USB Cables

USB cables are becoming ubiquitous as universal peripheral interface cables, audio/visual cables, Ethernet-over-USB, device-to-device serial connectivity, electrical system power, small electrical battery charging, control signal cables, and more. USB cables are frequently used to connect peripherals to computers in industrial systems, such as the touch displays for control interfaces to single-board-computers (SBCs) that often control the interfaces and communications for kiosks, electric vehicle chargers, etc. USB cables are used both internally and externally to electrical systems for peripherals, sensors, human interface devices, and other electrical hardware.

Therefore, there are several different types of USB cables and connectors. USB-A are still common connectors for industrial and computer peripheral applications, but USB-C are growing in use for all applications. Older styles, such as Micro-USB, Micro-B USB, USB-B, Lightning, and Mini-USB are still used in many equipment due to their economic benefits and compatibility with older equipment. USB cable assembly connectors can be straight but are also often available in various right-angle or 45-degree angle configurations.

Most USB cables are typically split into several categories based on the USB generation and their subsequent specifications. The current generation of the USB standards is USB 4.2 with up to 80 Gbps transfer speeds based on the USB-C connector. The USB cable is specified to a certain USB standard as well as a power rating for the type of power-over-USB capability the cable is rated for.

| USB Category Top Specifications | ||||

|---|---|---|---|---|

| Specification | Name | Speed | Max Distance | Connector |

| USB 1.0 | Low Speed | 1.5Mbps | 3 Meters | USB-A, USB-B |

| USB 1.1 | Full Speed | 12Mbps | 3 Meters | USB-A, USB-B, Mini-A, Mini-B |

| USB 2.0 | High Speed | 480Mbps | 5 Meters | USB-A, USB-B, Mini-A, Mini-B, Micro-A, Micro-AB, Micro-B |

| USB 3.0 | SuperSpeed USB 5Gbps | 5Gbps | 3 Meters | Type-A SuperSpeed, Type-B SuperSpeed, Micro-A SuperSpeed, Micro-B SuperSpeed, USB-C |

| USB 3.1 | SuperSpeed USB 10Gbps | 10Gbps | 3 Meters | Type-A SuperSpeed, Type-B SuperSpeed, Micro-A SuperSpeed, Micro-B SuperSpeed, USB-C |

| USB 3.2 Gen 1x1 (USB 3.0, USB 3.1 Gen 1, SuperSpeed) | USB 5Gbps SuperSpeed | 5Gbps | 3 Meters | Type-A SuperSpeed, Type-B SuperSpeed, USB-C, Micro-A SuperSpeed, Micro-AB SuperSpeed, Micro-B SuperSpeed |

| USB 3.2 Gen 2x1 (USB 3.1, USB 3.1 Gen 2, SuperSpeed+) | USB 10Gbps | 10Gbps | 3 Meters | USB-A, USB-C |

| USB 3.2 Gen 2x2 (USB 3.2, SuperSpeed+) | USB 20Gbps | 20Gbps | 3 Meters | USB-C |

| USB4 | USB 40Gbps | 40Gbps | 0.8 Meters | USB-C |

| USB4 Version 2 | USB 80Gbps | 80Gbps+ | 0.8 Meters | USB-C |

There are also hybrid USB cables that use fiber optic as the data signal carrying medium and copper conductors for the power and ground leads. Using fiber optic for the data signals provides much higher electromagnetic interference (EMI) and radio frequency interference (RFI) immunity and allows for much longer USB cables without the need for a “booster” interface in between the two end-destinations.

Fiber Optic Cables

Fiber optic cables are the backbone of high-speed and long-distance enterprise networking, data centers, hardline telecommunications, and internet infrastructure. Fiber optic may be used in industrial applications to connect between high traffic hubs, intranets, high-speed cloud services, and between interconnect points that require extremely high EMI/RFI resilience. Fiber optic cables are among the most efficient and highest speed hardline interconnects but require specialized equipment and interconnects.

There are several different types of fiber optic cable, but the most common categorization is single-mode fiber or multi-mode fiber. Single mode fiber is optimized for near-infrared (Near IR) wavelengths between 1300 nm and 1550 nm but can be used for a much wider range of light frequencies. Single mode is the most common type of fiber optic cable used for long distance telecommunications. Multi-mode fibers are larger core fibers that are designed for infrared light between 850 nm and 1300 nm. The larger core is less optimized (shorter range ~1 km) than single-mode fiber but allows for a much wider range of frequencies, and hence multiple light modes within the same optical waveguide (higher total data rate).

Fiber optic connectors can either be screw-on, snap-on, twist-on, or press. The type of fiber optic interconnect is often dictated by the application and can either be a standard style connector or a transceiver. The fiber optical classifications from the ITU are OM1, 2, 3, 4, and 5, and are related to the bandwidth*length product of the device. Fiber optic cables are also often described based on the transfer rate, either 10GBase, 100Base, 1000Base, 40GBase, or 100GBase. FIber optic transceiver form factors are usually one of the 6 main types: SFP, SFP+, GBIC, X2, XFP, XENPACk, QSFP+, and CFP.

| Fiber Optic Category Top Specifications | |||||

|---|---|---|---|---|---|

| Category | Max Attenuation (dB/km) 850nm / 1300nm |

Min OFL Bandwidth (MHz-km) |

Min EMBc Bandwidth (MHz-km) |

1Gb Ethernet Distance (m) | 10 Gb Ethernet Distance (m) |

| OM1 | 3.5 / 1 | 200 / 500 | 220 / NA | 300 / 550 | 33 / NA |

| OM2 | 3 / 1 | 700 / 500 | 950 / NA | 750 / 550 | 150 / NA |

| OM3 | 3 / 1 | 1500 / 500 | 2000 / NA | 1000 / 550 | 300 / NA |

| OM4 | 3 / 1 | 3500 / 500 | 4700 / NA | 1100 / 550 | 550 / NA |

| OM5 | 3 / 1 | 3500 / 500 | 4700 / NA | 1100 / 550 | 550 / NA |

| 1310nm / 1550nm (SM) | Min OFL Bandwidth (MHz-km) |

Min EMBc Bandwidth (MHz-km) |

1Gb Ethernet Distance (m) | 10 Gb Ethernet Distance (m) | |

| OS1 | 0.5 / 0.5 | N/A | N/A | >2,000 | >2,000 |

| OS2 | 0.5 / 0.5 | N/A | N/A | >5,000 / 10,000 | 10,000 / 40,000 |

Common Types of Fiber Optic Cable & Connectors

- OM1 Multimode

- OM2 Multimode

- OM3 Multimode

- OM4 Multimode

- OM5 Multimode

- OS1, Single mode

- OS2, Single mode

- Multi-position Optical (MPO)/MTP

- Universal LC

- Standard Connector (SC)

- Single Terminus (ST)

- Ferrule Core (FC)

- HFBR

- MT-RJ

- VF-45

- Opti-Jack

- FDDI

- ESCON

- MU

- E2000

- SMA 905/906

- D4

- BICONIC

- DIN

Coaxial Cables

Coaxial cables are a type of electromagnetic transmission line that are capable of carrying DC, low-power, precision-analog, high-speed digital, and RF signals. This cable type is similar to twisted-pair transmission lines except the ground/shield is external to the signal line, which is the center conductor of a coaxial cable. This use of the ground of the transmission line as an outer shield that completely incases the center conductor provides a high degree of electromagnetic shielding, and the transmission mode is transverse-electromagnetic (TEM) and is relatively efficient at carrying signals short, medium, and long distances.

Coaxial cables are used in virtually all areas of industrial and enterprise electronics, telecommunications/wireless communications, control, sensors, etc. As a function of the versatility of coaxial cables there are an extremely wide variety of both coaxial cables and connector types, which leads to a massive diversity of coaxial cable assemblies.

Common Coaxial Cable Types

- Formable

- Semi-Rigid

- Rigid

- Flexible

Rigid coaxial cables are prefabricated for specific applications but are the best performing coaxial cable. Semirigid coaxial cable can be formed using specialized tools and is high performing. Formable coaxial cable can be formed with less specialized tools, but like semi-rigid, once formed it cannot be reworked and maintain specifications. Flexible coaxial cable is the most common type of coaxial cable used in communications and sensing and can be bent and flexed a significant number of times as long as the minimum bend radius isn’t exceeded.

Old military standards for coaxial cables, RG, are still used today to some extent to describe some series of coaxial cables. There are also other cable variations based on how the cable is constructed, such as solid or stranded conductors and what type of dielectrics/jacketing are used. The materials and construction of coaxial cable determine what type of application the cable may be used in. For instance, there are jacketing and dielectric materials available that can allow for coaxial cable to be used in Plenum rated spaces, underground, oil/gas, high voltage (HV), or other extreme applications.

Example Coaxial Cable Series

- 100 Series

- 195 Series

- 240 Series

- 400 Series

- 600 Series

- Ultra-Flex Series

- RG174

- RG142B

- RG223

- RG58C

- RG188

- RG316

- RG58

- RG316

- 30-02003-LC

- 30-02001-LC

- TWCH-78-2

- LL142

- LL335i

- 402SS Series

- LC141TB / LC141TBJ

- LC085TB / LC085TBJ

- LMR-100

- LMR-195 / LMR-195-FR

- LMR-200 / LMR-200-FR

- LMR-240 / LMR-240-DB

- LMR-400 / LMR-400-DB

- LMR-600 / LMR-600-DB

Each end of a coaxial cable can be terminated by different types of connectors, even non-coaxial connectors. The type of connector and cable combination determines the cable assemblies’ specifications, either of which may be a limiting factor. This is why there are many cable assembly types that are typically used in certain applications as they meet those application standards and may have tradenames or brand-names that users recognize. Coaxial connectors and cables may also be rated as low loss, meaning that the cables are more efficient at carrying signals. For telecommunications, low-PIM cables and connectors may be used to mitigate the degrading effects of an EM phenomenon that coaxial transmission lines are susceptible too.

Common Coaxial Connector Types

- BNC / RP-BNC

- TNC / RP-TNC

- N-type (Precision, low-PIM, low-loss, HV, etc.)

- 7/16 DIN

- 4.3-10

- SMA / RP-SMA (Precision, low-PIM, low-loss, etc.)

- QMA

- MCX

- MMCX / RP-MMCX

- QMA

- SMB

- SSMB

- TRB

- M17/176-00002

- SMA-Nano

- U.FL

- 1553 TRB 3-lug

- LSZH 1553 TRB 2-Slot

Coaxial cable assemblies are often used as adapters and may have two different types of coaxial connectors on each end. This is helpful to eliminate the need for a distinct adapter. Different connector styles may also be used, including right angle, reverse polarity, bulkhead, or flanged. Most coaxial cables are 50 Ohm impedance transmission lines while some for broadcast, A/V, sensors, or other niche applications are 75 Ohm impedance transmission lines.

Test & Interface Cable Types Often Found with Coaxial Cables

- Banana

- Probe

- NMO / TAD Mobile Mount

- FME

- RCA

Coaxial cables are more lossy than optical transmission lines but require less costly and specialized tools/skills to work with and are more common for short and medium range communications and networking. These cables are also ubiquitous in RF applications, where many devices and components come in coaxial connectorized packages that are readily connected using coaxial cable assemblies.

D-Subminiature (D-Sub) Multiconductor Cables

D-Sub cable assemblies are used for a wide array of applications from military/defense to computer peripherals and networking technology. D-Sub connectors and cables are modular and versatile, and may support power, analog, high-speed digital, coaxial, triaxial, biaxial, fiber optic, and other interconnect types in the same multi conductor cable assembly. The heart of the D-Sub cable assembly is the D-Sub connector, which is shaped somewhat like a D. D-Sub connectors feature two rows of parallel contacts that are surrounded by a metallic conductive shell that is both ground and a shield, the hood. Many D-Sub connectors also have screw f ixturing on either side of the connector to ensure property insertion and secure mechanical connection.

There are some specific applications, such as aerospace, space, defense/military, radar, and others that rely on D-Sub connectors to serve as extremely rugged interconnects that can withstand high g-forces, shock, vibration, etc. This is why D-Sub cable assemblies are also widely used in industrial and enterprise settings. The number of conductors in a D-Sub cable assembly are typically part of the name of a D-Sub connector part, such as the DB9, DB15, DB25, DB50, etc. The D-Sub HD series is a high-density video connector used for PCs, often called a VGA connector, has smaller pins and closer spaced pins than typical D-Sub connectors, which is why it is separately called an HD15 connector. HD26 and HD44 are also a type of D-Sub commonly used in computer and networking technology applications that may be found in industrial hardware for serial/parallel communications and video/ display uses.

M8 & M12

M8 and M12 connectors and cable assemblies are often used in industrial applications for data and sensor interconnect applications. M12 connectors are a circular 12mm threaded connector head, while M8s are more compact at 8mm. These connectors use a threaded head with seals that enables reliable use of these connectors in extreme environments, including areas with lots of corrosive gas/liquids. M12/M8 cables may carry power and/or data signals and are even used for Ethernet or Fieldbus systems. These connectors are mostly used in industrial automation but may also be used with virtually any digital communication technology or for sensor signals.

Audio/Visual (A/V) & Display Cables (HDMI, DisplayPort, DVI-A/-D/-I)

The increased use of high-definition visual displays on machine and industrial equipment corresponds with a need for a wider range of display cables. Industrial visual systems also often require audio channels to be carried on the display interconnect or as separate audio interconnects. This is why digital display cable types that can carry both display and audio are growing in use in industrial and enterprise environments, while there are still an extensive number of applications that use legacy display cables and audio cables. Though audio cable technology has been relatively static for some time, display/video cable technology is advancing with new varieties and updated standards of common types every few years.

Common Display Cables

- HDMI (1.1, 1.2, 1.4, 2.0, 2.1, etc.)

- DisplayPort (1.2, 1.4, 2.0, etc.)

- DVI-A

- DVI-D

- DVI-I

Common Audio Cables

- XLR

- 3.5mm

- M12

- M8

- BNC

- RCA

- MIDI DIN

- USB

- FireWire

- TRS / TS

- Optical

Why Cable Assembly Choices Matter in Modern Networks

Cable assemblies are often treated as interchangeable, but in modern networks they directly affect reliability, signal integrity and long-term maintainability. This white paper explains the most common cable assemblies used today, including Ethernet, USB, fiber optic and coaxial, and how connector types, shielding and construction influence performance across different applications. This is a great resource for engineers and system designers who need to select assemblies based on data rates, environmental exposure and lifecycle requirements.

Conclusion

There is a massive diversity of cable assembly types used in modern industrial and enterprise applications. With the growing electrification of many previously mechanical/hydraulic systems and the demand for more sensors and control capability, the numbers and types of cable assemblies used in these applications will likely continue to grow. More recently, varieties of ethernet and other cable assemblies that support high-speed digital communications for wireless and conductive IP-based data transfer are becoming more commonplace. However, there are a dearth of legacy applications and hardware types that have converged on certain legacy connector and cable types that are still needed to maintain these older systems and these cables/connectors are still in demand.

Frequently Asked Questions

A: Standard Ethernet cables may fail in harsh environments. Industrial Ethernet assemblies are designed to resist vibration, chemicals, and temperature extremes.

A: With proper handling and protection from physical stress, fiber optic assemblies can last over 10 years.

A: They may cost more upfront but save significant labor and reduce downtime, making them cost-effective in the long term.

A: Yes, hybrid cable assemblies can carry both, but careful design is required to prevent interference.