M12 Connector Codes Deciphered

Download the Full Whitepaper (PDF)Executive Summary

Key Takeaways:

- The M12 connector coding system (A-, B-, C-, D-, X-, S-, T-, K-, L-codes) is designed to prevent mismating and ensure correct signal, data, power, or high-speed use.

- Each code corresponds to specific application domains; for example, A-code for sensors, actuators, and low-power signals; C-code for power applications; D-code for industrial Ethernet data; and X-code for high-speed data up to 10 Gb/s.

- Selecting the correct M12 code is critical in industrial automation environments to ensure compatibility, safety (voltage and current ratings), environmental robustness (IP ratings), and long-term reliability.

- Powering field equipment with M12 connectors is increasingly important; newer power-coded versions such as L-code support higher currents (e.g., 16 A) and help consolidate connector diversity.

- Standardization of connector codes reduces installation errors, ensures interoperability between manufacturers, and supports future-proofing of systems as automation and IoT continue to expand.

What Is an M12 Connector?

The boom of automation technologies is a direct result of the successful transition to electrical/electronic controls, power, and sensing that is dominating most modern technologies. This electrification enables automated control, data gathering, and intelligence that were previously unattainable. Part of this success story is the M12 connector. Due to the standardization of the M12 connector and the design-in versatility of this connector type, it has emerged as the preferred interconnect standard for the automation sector. M12 cables come in kits that are assembled by the user or as pre-wired, pre-molded, and pre-tested cables, which are generally the more popular solution as they are easy to use, install, and typically have high reliability figures.

Originally used for sensor interconnect, M12 connectors have evolved to now include configurations and pinouts for new applications and sectors beyond automation. This is why M12 connectors can be found that feature interconnects specifically designed for Ethernet, digital signals/data, analog signals, and power (AC/DC). There are even hybrid M12 connector configurations that allow for multiple signal types in the same connector. Regardless of the configuration, M12 connectors are designed for harsh industrial environments and include features that make this connector solution ideal for most environments.

M12 Connector Codes

M12 connectors are a circular 12-mm diameter threaded head that was originally designed for corrosive environments. From this, M12 connectors are designed with features to ensure they are waterproof and operate over a wide temperature range from -40°C to 85°C. M12 connector housings are most often made from highgrade stainless steels or plated brass/nickel to prevent corrosion and rust.

Given the modern diversity of applications M12 connectors are used in, the major stakeholders in M12 connectors have converged on a code-based nomenclature to describe the various M12 connector configurations to ensure compatibility. The M12 standards derived for this also dictate implementations and applications for the cordsets with the given codes. This helps to ensure that the appropriate cabling is always used for the right application, to avoid hazards, equipment damage, and defects. For instance, it could easily be tragic if medium voltage AC or DC was energized along the M12 connection meant for low voltage analog sensor signals. This is why the M12 standards for codes also include exact dimensions of the connectors/cables, environmental performance, mechanical behavior, and all relevant tolerances.

Of these, DIN EN 61076-2-101 is a long-established standard that covers M12 codes A, B, C, and D, which are designed for sensor and control signals mainly, but can account for low-voltage/low-power applications used for most sensor and light data Ethernet. IEC 61076-2-111 covers S, T, K, and L codings, which are used for AC and DC power. DIN EN 61076-2-109 covers X coding used for CAT 6 and higher ISO/IEC 11801 Ethernet to 10 GBit/s. DIN EN 61076-2-113 covers the Y coding, which is most often used for low power signal, power, and Ethernet transmission to 100 Mbit/s.

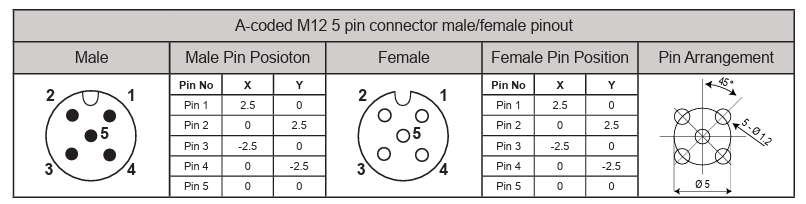

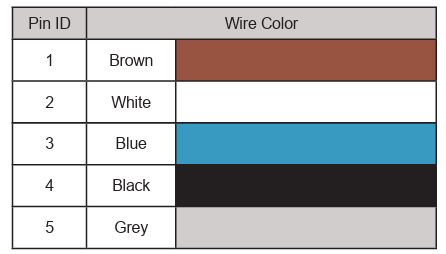

The keyways are made in such a way that mating of different types and pin number isn’t possible. It is not readily clear without additional labeling what exact type an M12 connector may be without examining the internal structure of the connector. This is why having a key insertion mechanic is necessary to avoid accidental interconnection of various circuits. Moreover, there are standard pinout color coding and pinout identification patterns that are generally accepted for M12 connectors. The exact pin designations and colors depend on the M12 connector code and number of pins. Each M12 connector is designed with exact positions for each pin with both x, y, and rotational tolerances.

A-coded M12 5 pin connector male/female pinout

Color coding for an A-code M12 5 pin connector.

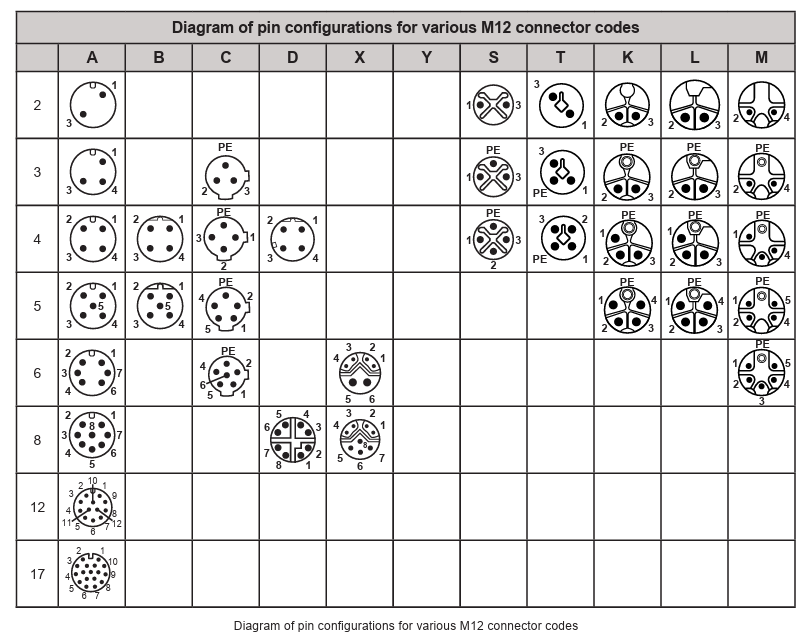

The keying and pinout patterns are different for every M12 connector code and pin number. With sufficient familiarity a user should be able to identify a given M12 connector by the keying to identify the code and the number of pins to determine the exact M12 connector style. Otherwise, a simple identification chart like that depicted in Figure 1 should be adequate. Some suppliers include the pin IDs on the M12 connector face, which can aid in troubleshooting and maintenance when a connector may need to be serviced or repaired.

Along with cable assemblies, there are also M12 adapters, field termination connectors, splitters, multi-channel splitters, and bulk-head connector types. Hence, color-coded pinouts are useful to ensure proper connections during installation/hook-up, troubleshooting, and maintenance.

Quick Guide to M12 Connector Codes & Pins

- A-code

- 2, 3, 4, 5, 6, 8, 12, and 17 pin configurations (4 and 5 pin are most common)

- Used for sensors, actuators, low power, and low-speed data transmission

- Code

- 4 and 5 pin configurations (5 pin is most common)

- Used for fieldbus applications such as Profibus and Interbus

- Code

- 2, 4, 5, and 6 pin configurations

- Used for sensors and AC supply power

- D-code

- 4 pin configuration only

- Used for 100Mbps maximum data transmission for industrial Ethernet, Profinet, Ethernet/IP, EtherCat machine vision, and other applications, most commonly up to Category 5e standards

- Capable of providing power via PoE (Power over Ethernet)

- X-code

- 8 pin configuration only

- Used for 10Gbps and high-speed data transmission applications, such as industrial Ethernet and machine vision, most commonly up to Category 6a or 7 standards

- Capable of providing power via PoE (Power over Ethernet)

- Y-code

- 6 and 8 pin configurations

- Hybrid connector style

- Used for both AC/DC power and data transmission in the same connector

- Designed for applications where this hybrid configuration can make the interconnect solution more compact

- S-code

- 2, 2+PE, and 3+PE configurations (4 pin, including the PE pin, is most common)

- Used for power supply up to 630V and 12A or 16A per contact

- Designed for AC power to motor operated switches, motors, frequency-converters, and other industrial equipment

- T-code

- 2, 2+PE, and 3+PE configurations (4 pin, including the PE pin, is most common)

- Rated to 63V and 12A or 16A per contact

- Designed for DC power connections for small DC motors and fieldbus power

- K-code

- 2, 2+PE, 3+PE, and 4+PE configurations (5 pin, including the PE pin, is most common)

- Used for power supply to 800V and 16A per contact up to 10kW

- Used for high power AC applications

- L-code

- 2, 2+PE, 3, 3+PE, 4, 4+PE configurations (5 pin, including the PE pin, is most common)

- Used for voltage up to 63V and 12A or 16A per contact

- Designed for DC power connections for PROFINET and PROFIBUS devices

- M-code

- 2, 2+PE, 3+PE, 4+PE, and 5+PE configurations

- Rated to 630V and 8A per contact

- Designed for 3-phase AC power connections

*PE typically refers to “Protective Earth”, this is a connection to ground that is used for safety purposes to protect users and equipment from electrical discharge in case of a fault. The PE pin is generally connected to the ground pin on an electrical supply plug or other connector ground. It is important to note that a ground pin in a connector may be a PE, but is not necessarily so, but every PE should only be used as a ground pin.

A-Code

A-code M12 connectors are also known as Micro-DC connectors and was one of the first styles of M12 connectors introduced. This style is widely used in factory automation applications, including sensors, actuators, control signals, and 1 Gbps data transmission. This connector can be used to power low-power DC motors and motor-operated switches. The data transmission on this connector is adequate for some machine vision applications, security, and Ethernet to 1 Gbps. The utility of this code is why A-code M12 connectors can be found in a wide range of industrial and enterprise applications from factory automation/control, transportation, agriculture, renewable energy, and telecommunications.

B-Code

B-code M12 connectors are specifically designed for use with fieldbus connections, including PROFIBUS and Interbus. Unlike other M12 connectors, the B-code is designed with a reversed single keyway. This allows for 2 distinct M12 connections to be mounted on the same panel without the risk of accidentally interconnecting the two systems. This is useful for installations that have different voltage/current configurations.

C-Code

C-code M12 connectors are sometimes also called Micro-AC and are typically only used for AC power applications. This could be bringing AC power to actuators, sensors, and other AC devices, such as factory automation equipment. These M12 connectors all have extended grounding pins and double keyways to ensure that improper insertion isn’t possible

D-Code

D-code M12 connectors are almost exclusively used for industrial Ethernet applications but may also be used for f ieldbus applications such as Profinet/Interbus, EtherCat, PoE (Power over Ethernet) or Ethernet/IP use cases. This code enables data transfer rates to 100 Mbps. The 4-wire setup of this connector accommodates 2-pairs of Cat 5e twisted pair cables. To allow for all 4 pairs of Cat 5e twisted-pair cables to be connected in single housing, 8-pin/wire A-code can be used.

X-Code

X-code is a more recent addition to the M12 connector styles. This code is now commonly used for high-speed industrial Ethernet applications and can transfer to 10 Gbps of data. This high rate of data transmission is possible with X-code connectors as the pairs of Ethernet wires are galvanically isolated using a metal structure within the connector housing. As many systems are moving to higher data rate Ethernet and transfer speeds, it is likely that X-code M12 will eventually replace A-code and D-code M12. X-code M12 connections can accommodate Cat 6A and Cat 7 connections and has 8 dedicated pins for full Ethernet 4-twisted pair connections. X-code is also capable of providing power via PoE (Power over Ethernet) to supported devices.

Y-Code

Y-code M12 connectors are a type of hybrid connector that includes 4 pins for data connections and 2 or 4 pins for power connections. This code has the same capability as D-code for data transmission but can also include 2 or 4 power pins that function similarly to A-code for a highly compact interconnect solution. Y-code connectors can be used for fieldbus applications and EtherCAT. The Y-code designation comes from the “Y” shaped face of the connector that is intentionally split to separate the data and power pins. This code is capable of up to 50 V AC/DC and 6A on the power pins or 0.5 A on the signal pins.

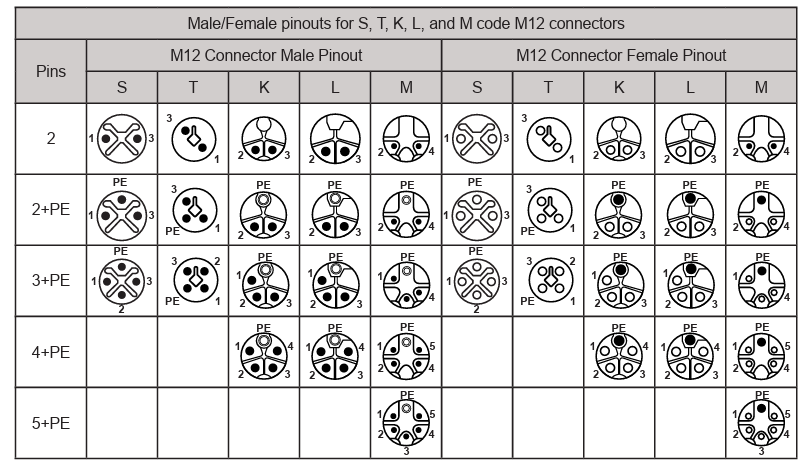

S-Code

S-code are among the newer M12 connector codes and will likely eventually replace C-code M12 parts. This code is designed for AC power applications to 630 VAC and 16A in either 1-phase, 2-phase, or 3-phase versions. The 3-phrase S-code connector is capable of 7.5 kW of AC power transmission, which makes it ideal for low-power AC motors, motor-controlled switches, and frequency converters.

Male/Female pinouts for S, T, K, L, and M code M12 connectors

T-Code

T-code M12 connectors are similar to S-code but are designed for DC applications to 63VDC and 12A per contact. This code is often used for fieldbus or Ethernet applications and can carry up to 750W of DC power, to power low-power DC motors/drives. It is likely T-code M12 connectors will eventually replace A-code connectors for DC power applications.

L-Code

Like T-code connectors, L-code M12 connectors are designed for use to 63V, but to 16A. This is ideal for high current but low voltage DC applications, such as fieldbus and Ethernet I/O boxes. L-code can also be made with a 4 pin with additional PE contact, where T-code is only available to 3 pin with PE contact.

K-Code

K-code M12 connectors are similar to S-code connectors, but some with an additional 4 pin and PE contact configuration. This code is also capable of 800V AC transmission with 16A per contact for a total of 10kW of AC power transmission per connector. This code is ideal for high power AC connections for motors and drivers.

M-Code

M-code M12 connectors are designed for up to 3-phase AC power transmission to 630V and 8A per contact. This code includes a PE for each pinout style except for a 2 pin style which does not include a PE contact.

P-Code

P-code M12 connectors are designed for up to 4 pin positions with a PE. These connectors are designed for data and can accommodate 2 twisted pair Ethernet connections at maximum pin positions. Though this connector type can be used for various functions it is generally used for EtherCAT applications.

Recommendations

- Check voltage/current/wiring requirements: For example, if you're supplying power-heavy field devices, use a connector rated accordingly (C- or L-coded) rather than a signal-rated A-code.

- Evaluate your application’s needs: Determine whether you need signal, fieldbus, Data-Ethernet, or power connectivity and choose the correct M12 coding accordingly (e.g., A for signals, D for Ethernet, C/L for power).

- Use proper keying and compatibility checks: Because connectors with different coding are not physically compatible, proper keying avoids accidental mismating.

- Consider environmental/industrial factors: Choose connectors with the required industrial IP rating (e.g., IP67) and durable construction suited for vibration, temperature, and humidity.

- Future-proof your system: If high-speed data or power redistribution might be required later, consider moving to connectors that offer higher ratings or codes designed for expansion (e.g., X-code for high-speed data).

- Document and label connectors clearly: Especially in complex automation systems, clear labeling of connector codes, functions, and wiring avoids maintenance errors and ensures correct replacement parts.

- Perform installation inspections and testing: Check that the connector mating is correct, shields/grounding are properly connected, and that the code selected matches the application.

- Train maintenance / installation staff: Ensure personnel understand the meaning of each M12 code, the risk of mismatching codes, and the style of connectors (male/female, thread size, etc.).

Learn How to Decode M12 Connector Codes and Choose the Right One

M12 connectors may look similar, but their coding schemes are designed to prevent costly and potentially hazardous mismatches. This white paper breaks down the full range of M12 connector codes—A, B, C, D, X and newer power-coded variants—and explains what each one is intended for, from sensors and fieldbus systems to Industrial Ethernet and high-current power delivery. This is a helpful guide for engineers working in automation and industrial networking who need to select the correct connector to ensure compatibility, safety and long-term reliability.

Conclusion

M12 interconnect is a highly versatile interconnect that is now widely used for factory automation and many other industrial applications. As the interconnect needs of these applications evolve, M12 interconnect is also evolving to accommodate higher data rates and higher power handling capability for multi-phase AC and DC applications.

Frequently Asked Questions

A: An M12 connector is a 12 mm circular, threaded connector originally designed for harsh industrial environments. It is waterproof, corrosion-resistant, and operates in temperatures ranging from -40°C to 85°C. M12 connectors are widely used in factory automation, sensors, actuators, industrial Ethernet, fieldbus systems, AC/DC power applications, and machine vision systems.

A: Not recommended they lack shielding and durability, leading to potential failures.

- A-code: Sensors, actuators, low-power DC, and up to 1 Gbps Ethernet

- B-code: Fieldbus systems like PROFIBUS and Interbus

- C-code: AC power applications

- D-code: Industrial Ethernet up to 100 Mbps

- X-code: High-speed Ethernet up to 10 Gbps

- S, T, K, L, M codes: Various AC/DC power applications

- Y-code: Hybrid connector for both data and power

Each code ensures safe and correct usage for specific voltage, current, and data requirements.

A: M12 connectors use unique keyways and mechanical coding specific to each connector type. This design prevents different codes or pin configurations from being accidentally connected. Additionally, standardized pin layouts, color coding, and strict dimensional tolerances ensure compatibility and safe operation.

A: Several M12 codes support Ethernet:

- D-code: Up to 100 Mbps (Cat 5e, 2-pair Ethernet)

- X-code: Up to 10 Gbps (Cat 6A/Cat 7, 4-pair Ethernet)

- A-code: Up to 1 Gbps in certain configurations

- Y-code: Hybrid connector supporting data (similar to D-code) plus power

X-code is commonly used for high-speed industrial Ethernet and machine vision applications.

PE stands for Protective Earth. It is a grounding connection used for safety to protect users and equipment from electrical faults or discharge. While some connectors include a ground pin, a PE pin is specifically intended for protective grounding and must only be used for that purpose. It is common in power-focused codes such as S, T, K, L, and M.