Cabling Requirements for Harsh, Industrial Applications

Download the Full Whitepaper (PDF)Executive Summary

Key Takeaways:

- Use PUR, LSZH, or TPE jackets to handle mechanical and chemical stress.

- Always choose IP67/IP68 connectors for outdoor or wash-down areas.

- Shielded cabling is essential in high-EMI environments.

- Follow TIA, IEC, and UL standards for performance and safety compliance.

- Future-proof designs with PoE, fiber backbones, and hybrid cabling.

Why Harsh-Environment Cabling Needs More Than Office Grade

Requirements for cabling and other interconnectivity infrastructure products vary widely when comparing traditional commercial environments such as office buildings to industrial environments which include factory floors, processing facilities and waste water treatment plants.

Standard commercial environments are generally free from fine particulates, liquids and extremes in temperature. While industrial environments contain some or all of these conditions as well as shock, vibration and EMI /RFI interference.

Traditional “controlled” environments

Traditional environment can include SOHO, SMB and large Enterprise networks where interconnect components are not exposed to dust, moisture, chemicals, or radio frequency and electromagnetic interference. For these installations there are many products to choose from which are available from a host of manufacturers and suppliers. Much of the infrastructure cabling is placed in the Plenum airspace above ceiling tiles or is run inside of walls where it goes untouched for years. Each IDF and the MDF are typically climate controlled with HVAC systems that keep the premise cabling as well as the active equipment such as switches, routers and servers at a constant temperature and humidity level.

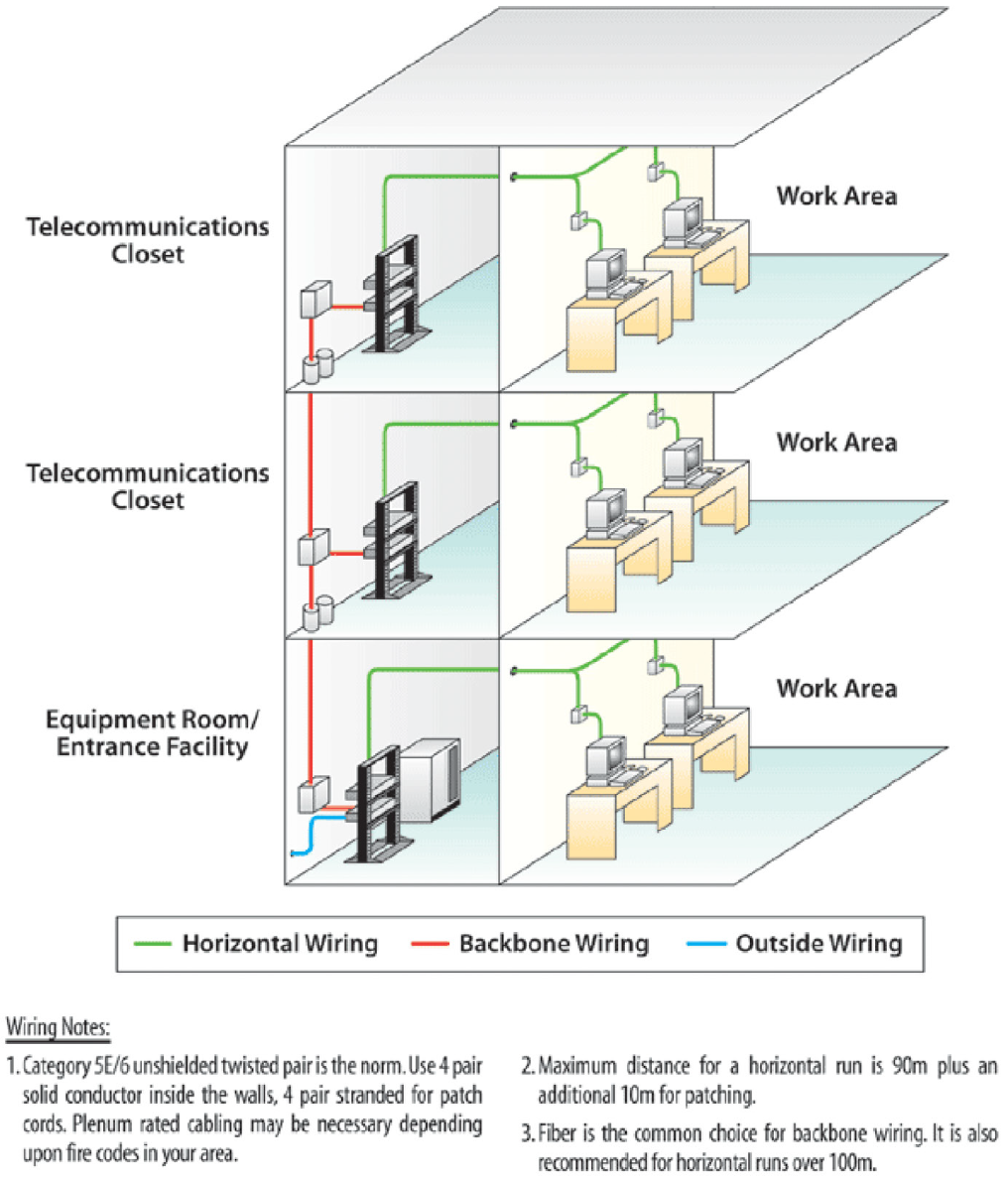

In these types of installations, a combination of copper UTP and Fiber Optic cabling is generally used. Fiber optic cabling is used for longer runs between floors of a building and also sometimes used underground either in a conduit or direct burial to connect multiple campus buildings. See Figure 1.

Fig. 1

Environmental & Mechanical Challenges of Industrial Cabling

Industrial environments often include manufacturing facilities, both onshore and offshore petroleum processing operations, coal mines, waste water treatment facilities and transportation systems including tunnels, subways etc. These harsh uncontrolled environments include both indoor as well as outdoor installations where temperature extremes, moisture, shock, vibration and exposure to chemicals are prevalent. When designing a cabling infrastructure for these types of conditions special consideration is required.

Materials, Jacket Types & Mechanical Protection

Often motors and generators are located right next to or in close proximity to network cabling. EMI and RFI can interfere with data transmission on a copper cable and cause downtime and errors. To lessen or eliminate EMI/RFI interference shielded cables and connectors must be used.

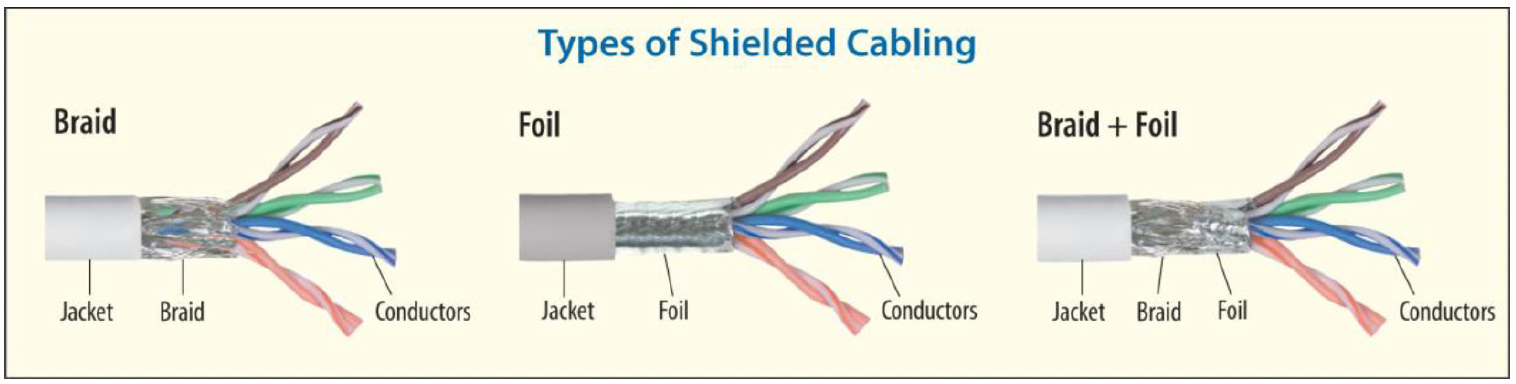

Typically, two types of cable shields are used, braided and foil. Foil shielding provides 100% coverage of the conductors but is hard to effectively terminate to connectors and offers high resistance which does not provide the best path to ground.

Braided shield generally offers 60%-85% shielding and can only offer about 95% coverage at best. The mass of the braid is higher than a foil shield and thus provides better conductivity and offers a good secure connection to the connectors at the cable ends providing an excellent ground. Many times shielded cables will utilize both foil and braided shields offering the highest level of protection from EMI/RFI. See Figure 2.

Fig. 2

When building a shielded cable plant it is important to use shielded cable, shielded connectors and shielded interconnection points such as patch panels in order for the shielding to be effective against EMI/RFI. Additionally, proper bonded grounding of all components is crucial to attaining effective shielding.

Jacket Types

Another consideration when designing a cabling plant in harsh environments is the cable jacket. In some cases, robotic equipment is directly connected via Category 5/5e or 6 cables that are constantly moving and require a cable that is constructed with a hi-flex, low friction jacket as well as robust connectors to ensure a high MTBF.

Other environments call for cabling that can be exposed to petroleum-based products or other chemicals. Traditional PVC jacketed cables would break down when exposed to these harsh liquids.

If protection of equipment or peoples’ lives is a design requirement then Low Smoke Zero Halogen (LSZH) jacketed cables should be considered. LSZH cables give off fewer toxic fumes that standard PVC based cable jackets. Typically, LSZH cabling is used in confined spaces such as mining operations.

Fiber Optics

The use of fiber optic cabling in industrial installations has grown over the past years as an alternative to traditional shielded cabling as fiber cabling is impervious to EMI and RFI. Additionally, fiber optic cables can extend great distances when compared to copper cables without the use of costly and cumbersome repeaters. Although fiber is more difficult to terminate in the field and costs more that STP cabling the price for fiber has continued to decline over time. With more offshore, lower cost fiber manufacturing this trend should continue.

In some cases fiber may only be needed in certain areas of an industrial cable plant near high EMI areas or between facilities where copper falls short due to distance limitations (see figure 3). If this is the case, relatively low-cost media converters can preserve the existing copper infrastructure investment and allow access to fiber runs where required.

Fig. 3

| Cable Distance Limitations | |

|---|---|

| UTP | 100 Meters |

| STP | 100 Meters |

| Multimode Fiber 50/125 and 62.5/125 | 2 Kilometers |

| Single mode Fiber 9/125 | 100 Kilometers* |

* Max distance depends on optics used

Cable Standards & Ratings for Rugged Installations

NEMA (National Electrical Manufacturers Association) and the IEC (International Electrotechnical Commission) are two standards groups which have devised rating systems for products such as cable assemblies, enclosures etc., which define the products resistance to dust, moisture, water immersion, and ice. The IEC’s rating is referred to as the IP or Ingress Protection rating. The table below outlines NEMA and IEC IP enclosure ratings. See Figure 4

Fig. 4

| NEMA Enclosure Type No. | NEMA Definition | IEC Enclosure Class |

|---|---|---|

| 1 | General-purpose. Protects against dust, light and indirect splashing but is not dust-tight; primarily prevents contact with live parts; used indoors and under normal atmospheric conditions. | IP10 |

| 2 | Drip-tight. Similar to Type 1 but with addition of drip shields; used where condensation may be severe (as in cooling rooms and laundries). | IP11 |

| 3 and 3S | Weather-resistant. Protects against weather hazards such as rain and sleet; used outdoors on ship docks, in construction work and in tunnels and subways. | IP54 |

| 3R | Intended for outdoor use. Provides a degree of protection against falling rain and ice formation. Meets rod entry, rain, external icing and rust-resistance design tests. | IP14 |

| 4 and 4X | Watertight weatherproof. Must exclude at least 65 GPM of water from 1-in. nozzle delivered from a distance not less than 10 ft. for 5 min. Used outdoors on ship docks, in dairies and in breweries. | IP56 |

| 5 | Dust-tight. Provided with gaskets or equivalent to exclude dust; used in steel mills and cement plants | IP52 |

| 6 and 6P | Submersible. Design depends on specified conditions of pressure and time; submersible in water; used in quarries, mines and manholes. | IP67 |

| 7 | Hazardous. For indoor use in Class I, Groups A, B, C and D environments as defined in the NEC. | - |

| 8 | Hazardous. For indoor and outdoor use in locations classified as Class I, Groups A, B, C and D as defined in the NEC. | - |

| 9 | Hazardous. For indoor and outdoor use in locations classified as Class II, Groups E, For G as defined in the NEC. | - |

| 10 | MSHA. Meets the requirements of the Mine Safety and Health Administration, 30 CFR Part 18 (1978). | - |

| 11 | General-purpose. Protects against the corrosive effects of liquids and gases. Meets drip and corrosion-resistance tests. | - |

| 12 and 12K | General-purpose. Intended for indoor use, provides some protection against dust, falling dirt and dripping noncorrosive liquids. Meets drip, dust and rust resistance tests. | IP52 |

| 13 | General-purpose. Primarily used to provide protection against dust, spraying of water, oil and noncorrosive coolants. Meets oil exclusion and rust resistance design tests. | IP54 |

As far as cable assemblies and IP ratings, proper termination is essential to qualify for an IP rating. The connectors and cable must be properly terminated per the manufacturer specifications to effectively meet an IP rating. If the assembly is not built correctly liquids, debris, and fine particulates can eventually cripple a network.

Learn How to Select the Right Cabling for Harsh, Industrial Environments

Choosing cabling for industrial environments isn’t about over-specifying everything. It’s about matching jacket materials, shielding and construction to the actual mechanical, chemical and EMI conditions in the field. This white paper explains how to select the appropriate cables for your application and how different environments drive specific cabling decisions, from PUR jackets for oil and chemical exposure to shielding strategies for high-EMI zones. It was created for engineers who need industrial networks that maintain performance over time.

Conclusion

When designing a network, the operating environment must be considered not just for active equipment such as Ethernet Switches but for cabling, connectors patch panels, wall plates and enclosures as well to ensure optimal network performance.

L-com, a global leader in the manufacture of wired and wireless connectivity products, offers a wide range of solutions and unmatched customer service for the electronics and data communications industries. The company’s product portfolio includes cable assemblies, connectors, adapters, computer networking components, and custom products, as well as Antennas, RF Amplifiers, Coaxial lightning and surge protectors, and NEMA rated enclosures. Trusted for over 35 years, L-com, which is headquartered in North Andover, MA, is ISO 9001: 2015 certified and many of its products are UL® recognized. www.L-com.com

Frequently Asked Questions

A: Any location with exposure to temperature extremes, moisture, vibration, chemicals, or EMI such as factories, outdoor sites, or transit systems.

A: No. Standard Cat6 cables use PVC jackets that degrade under UV or moisture. Use outdoor-rated or PUR-jacketed cables.

A: Polyurethane (PUR) is preferred for chemical-heavy and mobile applications.

A: Use STP or double-shielded cables with grounded connectors and proper routing away from motors or drives.

A: Choose fiber for long runs (>100 meters), high-EMI zones, or where electrical isolation is required.